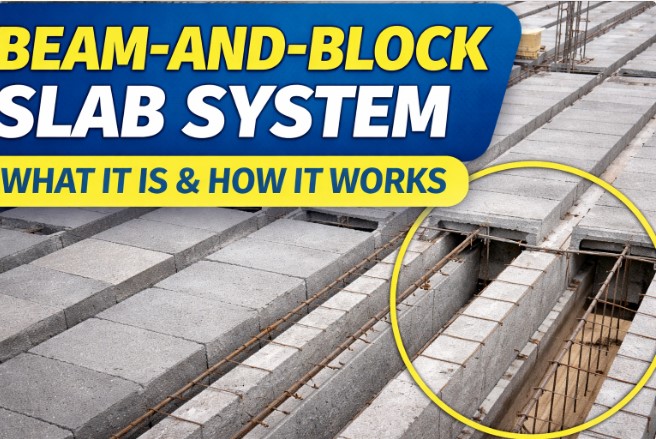

Beam-and-Block Slab Systems: What They Are, How They Work, and Why They Matter in Modern Construction

Introduction

In many construction sites across Nigeria, there is often confusion when block units are seen beneath an upper floor slab. Some assume it is ordinary blockwork being used to support a slab, while others believe it is a cost-saving shortcut. In reality, there is a proper, engineered system where blocks are used within a slab system—not as load-bearing walls, but as infill components.

This system is known as the beam-and-block slab system (also called rib-and-block slab). When properly designed and executed, it is a safe, efficient, and widely accepted construction method used globally.

This article explains what a beam-and-block slab system is, how it works, how it differs from unsafe site practices, and why Nigerian construction professionals should understand it properly.

What Is a Beam-and-Block Slab System?

A beam-and-block slab system is a suspended floor construction method made up of:

Precast reinforced concrete beams (ribs)

Lightweight concrete or EPS infill blocks placed between the beams

A structural concrete topping cast over the entire surface

The system forms a solid, load-carrying floor once completed, but the blocks themselves do not carry structural loads.

Instead, the precast beams are the main structural elements.

How the Beam-and-Block Slab Works (Load Path Explained)

One of the most important things to understand in structural design is the load path.

In a properly designed beam-and-block slab:

Live load + dead load → concrete topping → precast beams → load-bearing walls / beams → columns → foundation

Key points:

The beams carry the load

The blocks act as infill and permanent formwork

The topping concrete distributes loads evenly

At no point are the infill blocks relied upon as structural supports.

The Role of the Infill Blocks

The blocks used in beam-and-block systems are not ordinary sandcrete blocks used for walls.

Their functions include:

Filling space between beams

Reducing overall slab weight

Acting as permanent shuttering

Improving thermal and acoustic performance

They are not designed to carry slab loads, and they should never be treated as load-bearing masonry.

Why This System Is Often Confused on Nigerian Sites

On many sites, you may see:

Block units laid close together

Concrete cast over them

Little or no visible formwork

This leads to a dangerous assumption:

“The slab is resting on blockwork.”

In reality, the problem is not the beam-and-block system, but poor imitation of it.

Common site errors include:

Using sandcrete blocks instead of infill blocks

Absence of designed precast beams

No structural calculations

Casting slab directly on block walls

These practices are not beam-and-block construction—they are unsafe improvisations.

Difference Between Beam-and-Block Slab and Slab Cast on Blockwork

| Beam-and-Block Slab (Correct) | Slab Cast on Blockwork (Wrong) |

|---|---|

| Engineered system | Improvised method |

| Beams carry load | Blocks carry load |

| Designed infill blocks | Ordinary sandcrete blocks |

| Clear load path | Uncontrolled load transfer |

| Internationally accepted | Structurally risky |

This distinction is critical for safety and durability.

Advantages of Beam-and-Block Slab Systems

When properly designed and executed, beam-and-block slabs offer several advantages:

1. Reduced Formwork

The infill blocks act as permanent shuttering, reducing timber and labor costs.

2. Faster Construction

Precast beams allow rapid installation, speeding up floor construction.

3. Reduced Concrete Volume

Compared to solid slabs, less concrete is required.

4. Improved Quality Control

Precast components are produced under controlled conditions.

5. Cost Efficiency (When Planned Properly)

Although initial planning is required, overall project cost can be reduced through time and material savings.

Structural and Professional Considerations

Before adopting this system, the following are essential:

Structural design by a qualified engineer

Correct beam sizing and spacing

Adequate bearing length on walls or beams

Proper detailing of reinforcement and topping slab

Supervision during installation

Beam-and-block slabs are not a shortcut—they are a designed system.

Relevance to Nigerian Construction Practice

In Nigeria, this system is still underutilized, mainly due to:

Limited awareness

Confusion with unsafe block-supported slabs

Lack of local precast suppliers

However, as the industry moves toward:

Faster construction methods

Reduced material waste

Better quality control

Beam-and-block slabs represent a viable modern construction solution, especially for residential and low- to medium-rise buildings.

Key Takeaway

A beam-and-block slab system is an engineered structural floor system where precast beams carry the load and blocks serve only as infill—not load-bearing elements.

Confusing this system with casting slabs directly on blockwork is a serious construction mistake that can compromise structural safety.

Conclusion

Understanding the difference between engineered construction systems and unsafe site improvisations is critical for improving building quality in Nigeria. Beam-and-block slab systems, when properly designed and supervised, offer an efficient and safe alternative to conventional solid slabs.

As construction professionals, students, and stakeholders, embracing correct knowledge—not assumptions—is key to building structures that are safe, durable, and fit for purpose.

.jpeg)

.jpeg)

.jpeg)

Comments

No comments yet..!

Write a Comment